Here’s what you need to know about this popular home type — including why they tend to be more affordable than traditional builds.

If your builder, agent or lender has suggested a prefab home, it may be for a good reason. Prefabricated homes — those built in a factory and shipped to a homeowner’s land site — are piquing buyer interest thanks to their relative affordability and availability.

Amid supply chain delays, a labor shortage and a dearth of existing home inventory, prefab homes can be an attractive alternative to “stick built” single-family homes. Read our guide to find out if prefab homes are right for you and how to finance one.

What is a prefab home?

Simply put, prefab is short for prefabrication. This is the practice of building housing components in a factory before transporting them to a job site for assembly.

Prefab is an umbrella term that can refer to modular/manufactured homes, mobile homes, container homes, kit homes and accessory dwelling units (ADUs).

Manufactured homes are a type of prefab home.

The National Association of Home Builders Modular Home Building Council defines these homes as “built in one or more sections in a factory, then transported and installed on a permanent foundation at the home site.” The organization assures prefab homes are held to the same quality standards and building codes as site-built homes.

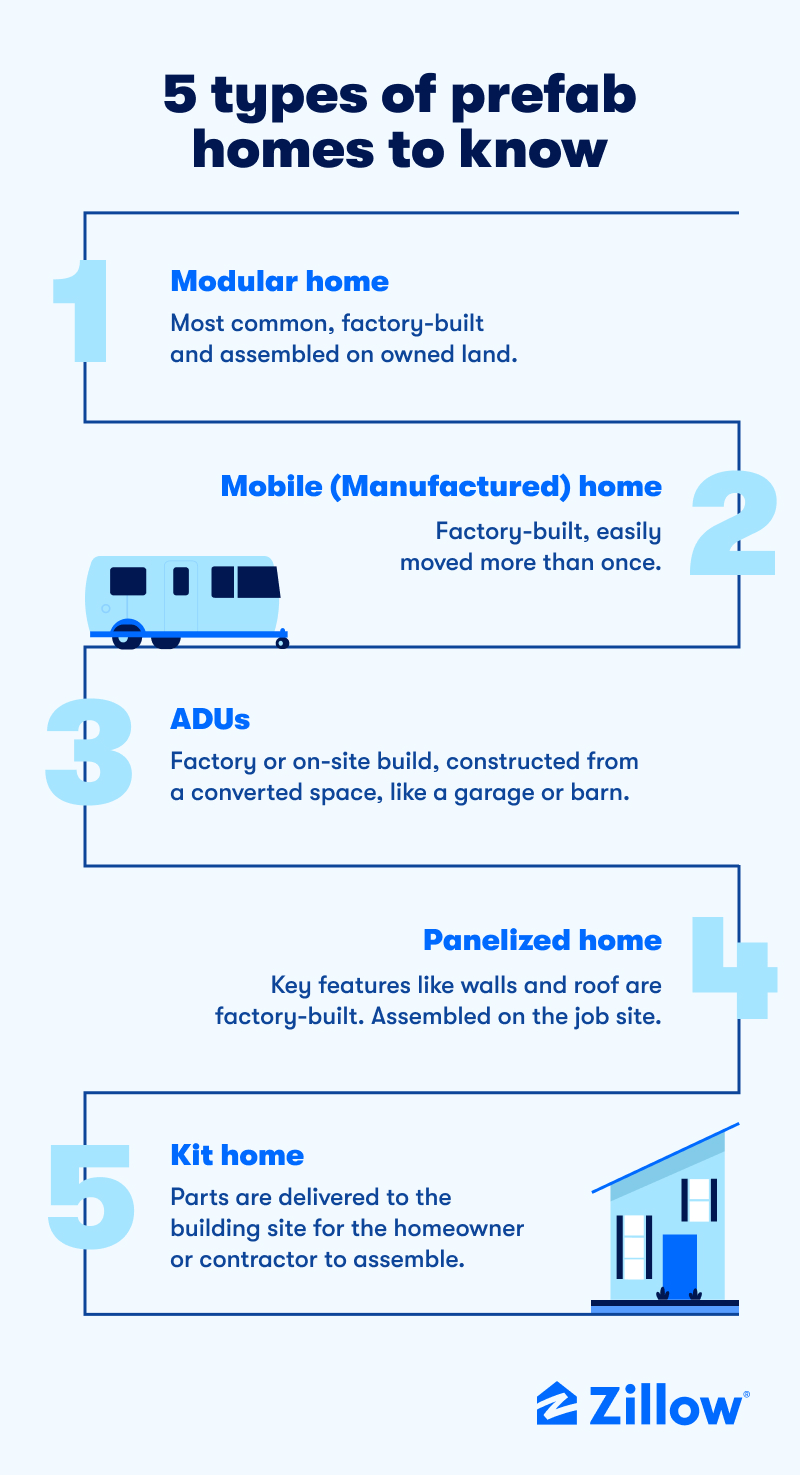

A closer look at five prefab home types

Modular home: This is the most common type of prefab home. Builders construct modular homes in a factory and assemble them on owned land where it stays permanently. Unlike some manufactured homes, a modular home will appreciate in value like traditional real estate.

Mobile (Manufactured) home: This type of home is also factory built, but it is constructed in a way that makes it easily moved more than once. Mobile homes are often placed on rented land and can be moved to other lots over time.

ADUs: Accessory dwelling units may be constructed in a factory, be built on-site or constructed from a converted space, like a garage or barn. ADUs are meant to be additional living spaces and placed on land next to a primary dwelling.

Panelized home: These homes are not modular. Instead, key features like walls, the roof and flooring are constructed in a factory as panels. These are then transported to the building site and added to the traditionally framed home.

Panelized home

Kit home: Ambitious homeowners who want to build their own home can choose a kit. With kit homes, parts constructed by a manufacturer are delivered to the building site. The homeowner (or hired contractor) assembles the pieces themselves on a traditional frame.

What does a prefab home look like?

Prefab homes are most commonly associated with contemporary layouts, floor plans and architectural features. However, manufacturers do offer a wide range of material choices. These can range from traditional to eco-friendly. They also come in a variety of styles, from grand colonials to cozy bungalows.

Materials

Or Michaelo, the founder of The Home Gallery, which offers factory-built homes designed by architects for home buyers in California, says most prefab homes use the same core materials as those built via traditional on-site construction methods. These include wood framing, drywall, plywood, tile, wood and flooring.

The main difference? The base of the frame is on a metal chassis or flatbed. This is so that the home can be transported or craned into its homesite. “Since factory-built homes are intended to be transported over long distances through fairly rough conditions, they are required to be built much stronger and more stable than traditional on-site construction,” Michaelo says.

After transport and assembly, landscaping goes in and it’s nearly impossible to tell from driving by whether the home was built in a factory or on-site.

Size/Floor Plan

Home buyers can build prefab homes in a range of sizes, from mansions to weekend cabins. The minimum size for a factory-built home that meets the stringent federal standards starts at 425 square feet. It must have one bedroom, one bathroom and a full kitchen.

“This would qualify as an ADU,” Michaelo explains. “Many zoning regulations [in California] require that a main residence is a minimum of 800 square feet. Our clients most commonly purchase homes between 900 to 1,600 square feet and choose their preferred bed and bath configuration.”

Of course, a prefab’s size needs to comply with local zoning laws for the desired location.

A 2 bed, 2 bath, 934 sq ft “Comet” model prefab home by The Home Gallery. Photo by Cristopher Nolasco.

Style

The sky’s the limit on style. When working with a builder, you can customize your home’s interior and exterior to fit your dreams and needs.

When Humberto Marquez, a licensed real estate agent, helps his clients find their dream properties, he makes sure they’re aware of the customization and flexibility of prefab options.

“While some prefab homes are built using standardized designs and materials, many prefab manufacturers offer a wide range of options and features that can be customized to meet the specific needs and preferences of the homeowner,” Marquez says. “This can include everything from the layout and floor plan of the home to the materials and finishes used, to the appliances and other features included. This can allow you to create a unique and personalized home tailored to your specific needs and lifestyle.”

The inside of a “Comet” model prefab home by The Home Gallery. Photo by Cristopher Nolasco.

Do I hire a real estate agent to buy a prefab home?

You can hire an agent to assist with a prefab home purchase, but it’s not imperative. You can also go directly to the home manufacturer for guidance.

Marquez says it’s beneficial to use a real estate agent as they can help you understand the prefab home building process and the differences between going that route or with a traditional build.

“The agent can help the buyer understand any legal requirements or regulations related to prefab homes,” he says. “They can also provide guidance on obtaining the necessary permits and approvals. Overall, the agent can serve as a valuable resource for the buyer, helping them make informed decisions and providing support throughout the process of purchasing a prefab home.”

When it comes to finding and buying the land where your prefab home will be built, an agent can help here too. Marquez says he is happy to explain to his clients the differences between residential, commercial and agricultural zoning and the potential uses and restrictions of each.

“The agent can provide information about the local real estate market, including current land prices and trends and can assist the buyer in identifying properties that meet their needs and budget,” he elaborates.

An agent can also assist with the negotiation of the purchase price and guide the buyer on financing options.

What does a prefab home cost compared to traditionally built homes?

Buyers should expect to spend $90 to $150 per square foot on a finished modular (prefab home), according to Modular Today, a publication that offers consumer reviews of modular products, reports that, depending on options chosen in the building process.

A prefab home is often more affordable than a traditional single-family home. Michaelo estimates his prefabs typically save buyers 25% to 30% compared to an onsite build.

Warehouse with prefab container houses.

Building in a climate-controlled factory saves on materials, time and labor costs. “Materials are cut exactly to size with little or no waste, and labor works in a highly efficient assembly line, completing an entire home within eight to 12 days in the factory and another four to six weeks on location,” Michaelo says. In total, his clients can expect to skip about six to seven months of construction and labor days per home. This estimate takes into account current labor shortages and supply chain issues.

Timelines and costs will vary from builder to builder. For example, Green Diamond Builders, Inc. in Delaware completes their prefab homes in about eight to 10 weeks.

As you think about the costs associated with having a prefab home built, Mortgage Loan Officer Juan Rodriguez from Zillow Home Loans, LLC adds, “Buyers should understand there are additional costs besides the home and land, such as making sure there are services on the land (electricity, water source/public or well), buying a septic tank, a foundation to place the home on as well as local permits — not to mention the time it takes to get it all done and moved in.”

How does financing work on a prefab home?

In most situations, the prefab home manufacturer will have an in-house lender or preferred lending partner. This person or team will facilitate both the financing of the land and the home, according to Rodriguez.

If the home buyer already owns the land, the financing will just be for the prefab home itself.

“There are lenders that offer traditional financing for Fannie Mae, Freddie Mac, FHA and VA,” Rodriguez explains. “The limits to traditional lending for a mortgage is that a prefab home must sit on land owned by the borrower. If you purchase a prefab home and place it in a mobile home park whereby you rent the ‘space,’ then traditional mortgages do not apply.”

Is a prefab home right for you?

A prefab home could be right for you if you’re on a tighter timeline and budget. You may also consider one if you’re looking to downsize to a smaller space. Alternatively, you may be looking to add an ADU to your existing property. Michaelo says he’s noticed an uptick in buyers seeking prefabs in both of these circumstances.

For ADU-seekers, there are a multitude of factors fueling interest. Some are hoping to increase their property value. Others plan to use it as a rental for passive income or house extended family members.

As you consider your purchase, discover which type of home is your favorite in 21 Different Types of Homes, or learn more alternatives to conventional homeownership in 16 Alternatives to Buying a Single-Family House.